Blog | Reading Time 2 minutes

The Art of Bacteria Production in St. Simon

By using our WildBrew™ bacteria, brewers can be confident in the flavors that will be produced, as well as whether a particular strain is sensitive to hops, all while reducing the risk of contamination. Additionally, they can determine the optimal temperature required to achieve the desired level of acidity. Although this may sound straightforward, it is the culmination of over a century of fermentation expertise. In this article, we will take you behind the scenes of our bacteria plant in France.

Control and know-how are everything in the micro-organisms game

Lallemand has been a global leader in fermentation and production since its establishment in the 19th century. With nine bacteria production facilities globally, one of the main production plants, St. Simon (Cantal), is located in France. The production of bacteria is a complex process that requires expertise, experience, and attention to detail. As a primary producer of microorganisms, we fully control our production process from the lab to packaging. This control helps ensure the quality, the safety, and consistency of our products for all brewers. This assurance is possible because the company conducts tests at every stage of the production process, from development to packaging, to guarantee the quality and flavor that helps brewers achieve consistent results in beer production.

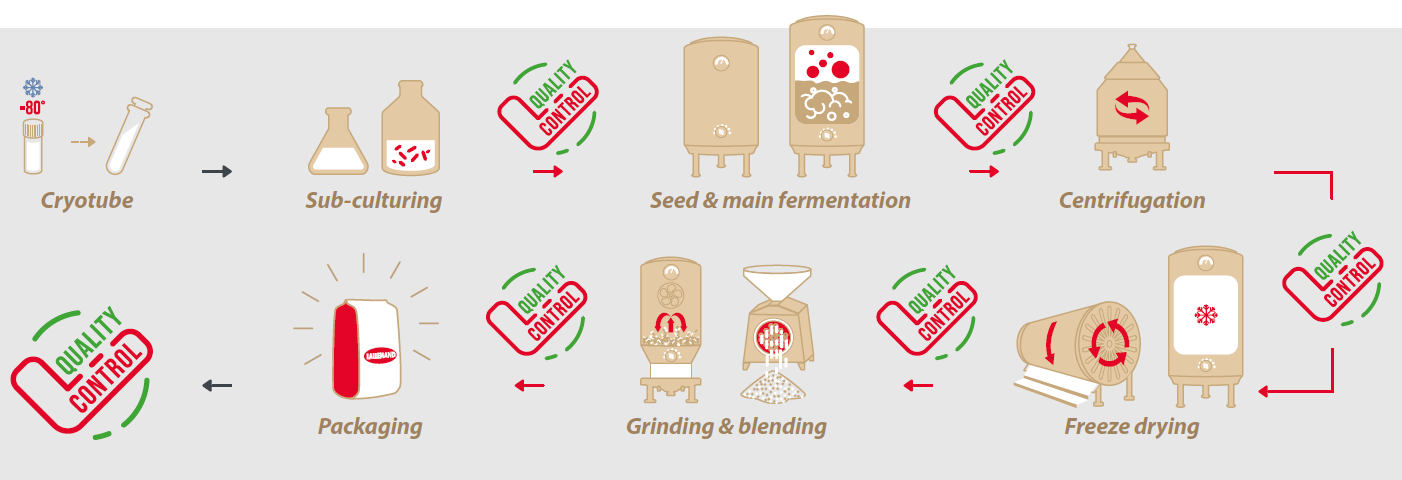

Understanding the production process

The production of bacteria at the St. Simon plant involves a combination of science, technology, experience, and history. The process starts with the selection of the best bacterial strains for specific applications. The company’s experienced experts oversee the development and fermentation of these strains. Fermentation takes place in large tanks that are constantly monitored and controlled to ensure that the conditions are optimal for bacterial growth. After fermentation, the bacteria are harvested and processed using state-of-the-art technologies. The bacteria are carefully freeze dried and packaged to maintain their quality and efficacy. Every batch of bacteria is tested and analyzed to ensure that it meets the company’s high standards for purity, potency, and quality.

St. Simon, production amid a rapidly growing market

The St. Simon plant in France is a vital part of Lallemand’s global network of yeast and bacteria production facilities. The plant’s location in France is in the heart of one of the world’s fastest growing brewing regions. Lallemand’s commitment to quality and innovation is evident in its investment in research and development. The team also works to continuously improve the safety and efficacy of its products, making them safer and more effective for customers worldwide. It is worth noting that Lallemand’s expertise in fermentation goes beyond brewing. Today, the company produces bacteria for several global applications, including specialty cultures, wine, yogurt, health solutions and animal nutrition.

Published Apr 26, 2023 | Updated Jul 20, 2023