Blog | Reading Time 3 minutes

An Examination into the Sensory Advantages Offered by a Novel Hybrid Maltose-negative Saccharomyces cerevisiae strain

Low and non-alcohol beer production differs from traditional beer production in a number of ways, most notably in sensory composition. These sensory differences are a result of different factors, with yeast being a primary driver. This article dives into how a novel hybrid maltose-negative Saccharomyces cerevisiae strain offers flavor and sensory advantages to low and non-alcohol beer production.

Much has been talked about regarding the sensory aspects (or lack thereof) of many non-alcohol beers and low alcohol beers (NABLAB) on the market. Depending on production method and/or yeast strain selection brewers are often faced with a myriad of choices with regards to flavor matching these beverages with traditional beer flavors. Several reasons for this conundrum exist, primarily having to do with a shortened fermentation time and/or yeast selection which hinders the utilization of aldehydes.

Aldehydes are flavor active compounds that form during the mashing and boiling process of wort production. 3-methyl butanal, 2-methylbutanal and methional are some of the more common aldehydes; these contribute worty or sweet flavors if they are not properly reduced to their primary alcohols. This reduction normally occurs in traditional beer fermentation through yeast metabolism. However, in a shortened or arrested fermentation, common with the production of low or non-alcohol beers, the extent of this reduction may be limited.

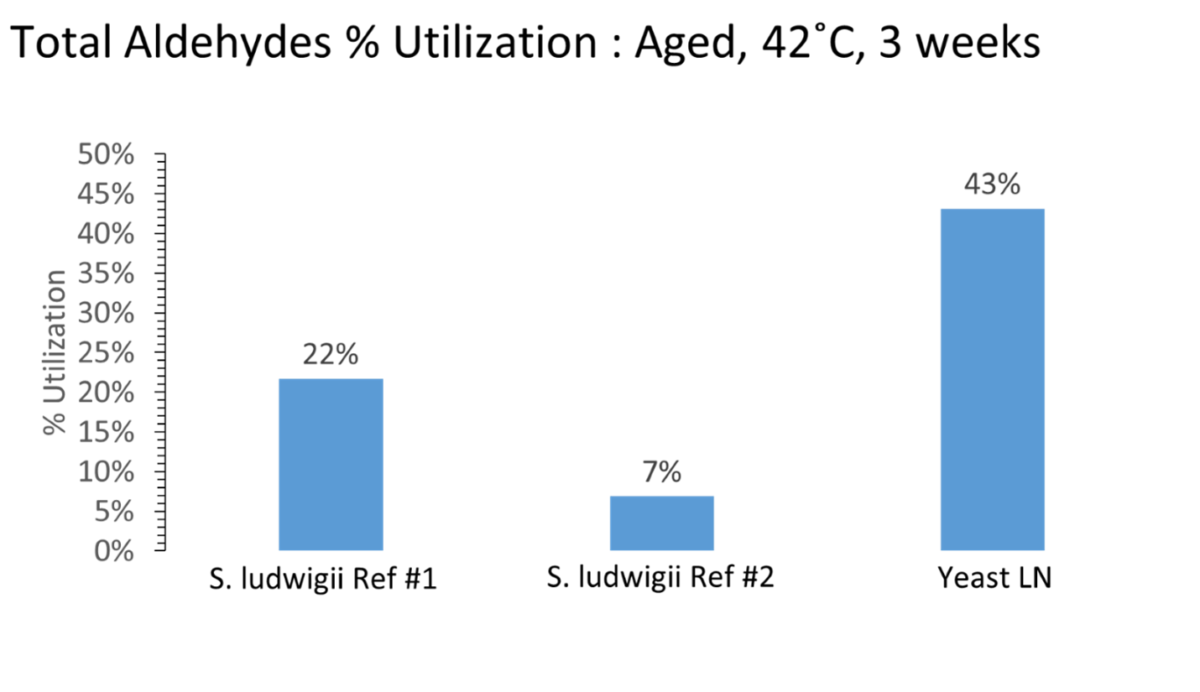

Yeast strain plays an important part in aldehyde reduction. This knowledge underpinned a study conducted to determine the different levels of aldehyde utilization by various maltose negative yeasts. It was found that LalBrew LoNa™, a hybrid Saccharomyces cerevisiae strain, exhibits good aldehyde utilization (43%) compared with other maltose negative yeast strains (Figure 1). These findings were also corroborated with questionnaire data collected from trial brewers who noted the absence or only slight wort character of LoNa™.

Figure 1

*“Yeast LN represents LalBrew LoNa™

Another perceived quality disadvantage of low or non-alcohol beer is the lack of substantial flavors complexity. This, in part, is related to diminished secondary metabolites such as esters and fusel alcohols, due to a shortened fermentation time and non-Saccharomyces cerevisiae yeast selection.

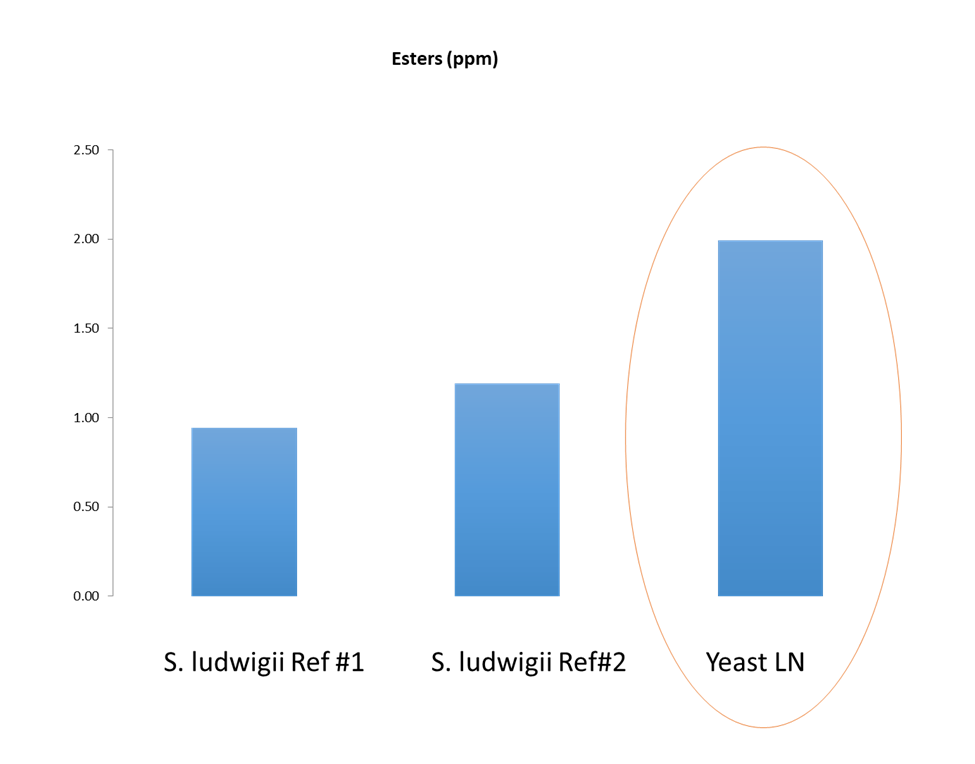

Industrial brewing strains are prized for their subtle complexity – fueled by a carbon and nitrogen rich substrate and a hallmark of Saccharomyces cerevisiae metabolism. LoNa™ being entirely derived from domesticated S. cerevisiae has demonstrated the capacity to produce a higher concentration of esters compared to other maltose negative strains in part because it is a S. cerevisiae strain (Figure 4).

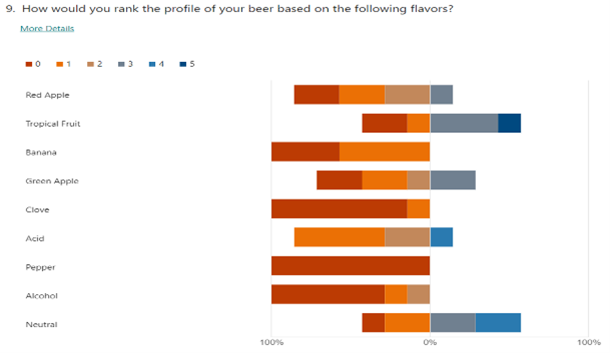

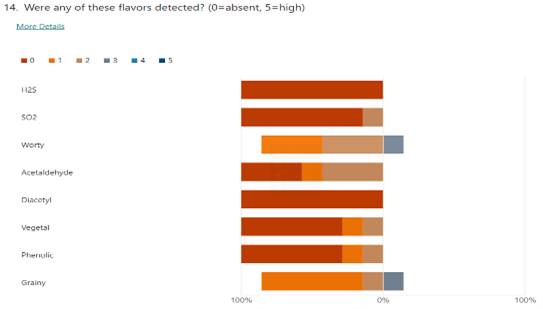

During preliminary trials, brewers and sensory panels were asked to rank LoNa™ on a common descriptive lexicon. Despite the diverse fermentation conditions among multiple breweries, favorable sensory characteristics were attributed to low-alcohol beers fermented by LoNa™ (Figure 5 & 6). This was based on a level of intensity ranking of 1 – 5.

Figure 2

Figure 3

Figure 5

*Figures 5 and 6 were taken from post commercial trial survey data provided by brewers after testing LalBrew LoNa™ in commercial conditions.

Summary

The production of low and non-alcohol beers presents numerous challenges, including shorter fermentation times, increased post-processing, inherent flavor perception differences due to the absence of flavor-active ethanol, and differing consumer expectations for this product category. As a result, achieving traditional beer-like flavors in low and non-alcohol beers can be difficult.

While there is no cure-all for immediately and economically resolving these issues, LoNa™ provides a rather unique tool for brewers to create organoleptically acceptable (and even exceptional) low and non-alcohol beers, with flavors closer to those found among traditional beers. Being a 100% domesticated Saccharomyces cerevisiae, LoNa™ leverages familiar metabolism while potentially revolutionizing new product development.

Despite the benefits of using LoNa™, it is crucial for brewers to remain vigilant in ensuring the safety and stability of the final product, as is the case with all low alcohol beverages. While low alcohol beer offers an attractive option for health-conscious individuals, it presents similar challenges to those faced by soft drink manufacturers.

Published Jul 28, 2023 | Updated Feb 1, 2024