Blog | Reading Time 3 minutes

What’s up with the worty flavor in NABLAB?

One of the most noticeable issues with non-alcohol beers and low-alcohol beers (NABLAB) is that flavor often does not match or compare with traditional beer flavors. The primary reason for these substantive flavor differences is the production process of these beverages. NABLAB can be made through physical or biological methods, with the latter relying upon maltose or maltotriose negative yeasts.

There are advantages and disadvantages to each method of production (discussed in our extensive NABLAB Best Practice), but as our expertise is in yeast, we are going to focus on the biological methods and why NABLAB beverages often taste sweet or worty.

Fermentation considerations when producing NABLAB

As the goal of NABLAB production is to produce a beverage with a lower alcohol concentration than a traditional beer, it comes as no surprise that the brewing and fermentation processes are approached from a different perspective.

To begin with, the starting gravity for NABLAB beverages is usually quite low (around 6 degrees Plato) and the mashing temperature is quite high (to ensure there is little glucose formation). Carrying onto to fermentation, using a yeast that does not ferment maltose or maltotriose (a maltose-negative and maltotriose-negative yeast) and the low concentration of fermentable sugars translates into a shorter fermentation time (3-4 days) than

usually seen in traditional beer fermentation.

A shorter fermentation time (or limited fermentation) has consequences for flavor active compounds, often resulting in these compounds not being fully metabolized, thus creating impactful flavor differences compared to a traditional strength beer.

Let’s talk about aldehydes

One of the most common sensory descriptions of NABLAB products is that they taste “sweet” or “worty”. These flavors are typically attributed to the presence of flavor-active aldehydes that are formed during the malting process and the mashing and boiling stages of wort production. Aldehydes are formed by different pathways including enzymatic oxidation of fatty acids, Maillard reactions, Strecker degradation, and degradation of bitter acids2.

The most prevalent aldehydes are:

- 3-methyl butanal – tastes of malty, chocolaty, cherry, almond

- 2-methylbutanal – tastes of almond, apple-like, malty

- methional – tastes of cooked potatoes, worty

Ordinarily, these aldehydes are reduced to their primary alcohols through yeast metabolism that occurs during a standard fermentation. However, in a limited or arrested fermentation, aldehydes are not reduced as efficiently, thus creating more of these wort or sweet flavors.

How to choose your brewing strain for NABLAB

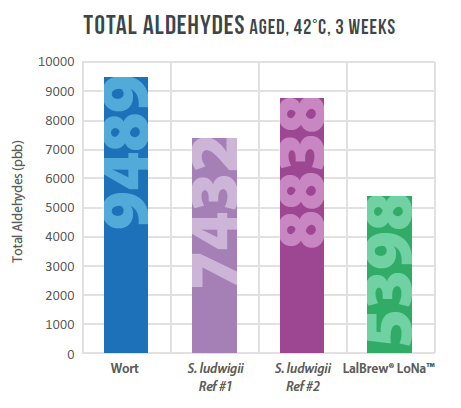

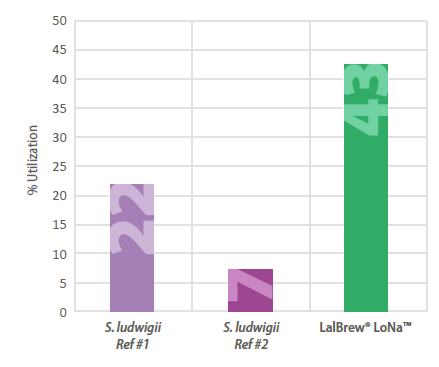

Because of these production constraints, yeast strain selection becomes an important tool for brewers to consider. This is especially true as different maltose-negative yeast strains have varying degrees of aldehyde utilization, as seen in Figures 1 and 2. In general, Saccharomyces cerevisiae strains are able to metabolize these aldehydes to a larger extent than other maltose negative yeast strains (S. ludwigii for example). The result of this metabolism is a reduction of aldehydes, which translates to a fresher and cleaner tasting NABLAB beverage that is closer to a traditional beer with significantly improved sensory characteristics Aldehyde utilization in NABLAB fermentation illustrates one of the many ways in which these beverages differ from full strength beer fermentations. For brewers embarking upon their non-alcohol beers and low-alcohol beers production journey, understanding these flavor and production differences will help them make better tasting NABLAB for all to enjoy.

Figure 1

Figure 2

Published Oct 6, 2023 | Updated Feb 2, 2024