Blog | Reading Time 1 minute

Quality and security at the service of brewers and breweries

Lallemand Inc. prides itself to provide our customers products of the highest quality standards that guarantee predictable performance. This starts with carefully managed yeast and bacteria cultures from our own culture collection up to our customer-oriented logistics. Strict quality control is implemented at every stage from the slant culture that is used to start a production through the various stages of production to the logistics platform. In addition, Lallemand Brewing has set up a series of brewing specific tests.

“Our mission is to supply safe products of consistent quality and competitive value, which meet or exceed our customer’s needs. We continuously improve our processes, products and services.“ Francine Leblanc, VP Quality Insurance, Lallemand Inc.

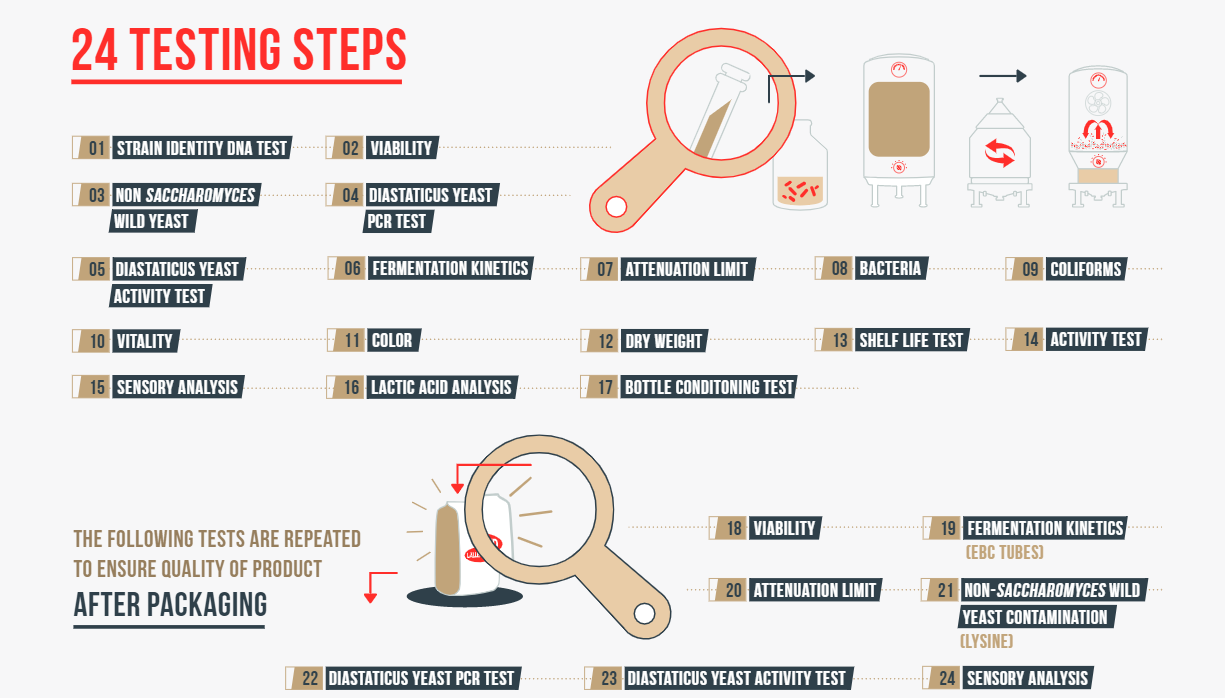

Indeed, one of the advantages of dried yeast is that the stability and long shelf life allows us to perform each of these 24 tests for every batch. Some of these tests will take weeks to produce a conclusive result. For instance, beer fermentations in our standard wort are done with samples of every production to monitor lag phase and overall fermentation time as well as apparent attenuation to ensure the yeast ferments to its specification. After a short storage period the bottled beer is tasted by a trained tasting panel to confirm the aroma meets the flavour profile of the strain and no off-flavours are produced.

All these tests are done on the bulk yeast after every production and again after the yeast is packaged in its final commercial pack to ensure you the highest quality standard and the best brewing experience.

For more information about our quality control procedure, download our Quality and Security brochure.

Published Dec 15, 2020 | Updated Jul 12, 2023

Related articles

Need specific information?

Talk to an expert