Technical Paper | Reading Time 3 minutes

Lager Brewing Made Easy

Lager is the most popular category of beer in the world. While lager beers can vary in color and flavor, light lagers such as pilsner are by far the most consumed beer style worldwide, so much so that the word “lager” is synonymous with light lager styles.

Simple ingredients and a unique lager yeast species defines a lager recipe.

The recipe for lager brewing may appear simple, but the process can be more difficult than ales. All lagers share a delicate, clean and balanced flavor profile. Sensory defects cannot be masked by the complex flavors of malt and hops. Avoiding sensory defects requires special attention to the recipe, quality control, and management of the brewing process.

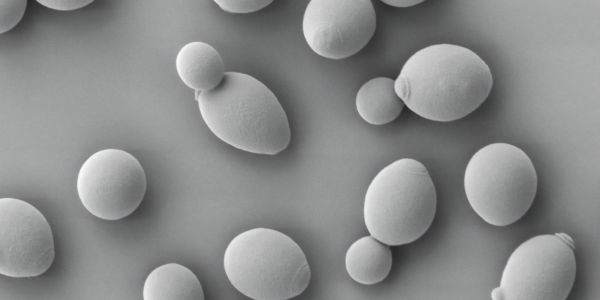

Lager brewing starts with the selection of high-quality raw materials. A low mineral water is combined with a simple malt bill of lightly kilned malts and adjuncts. The hop profile is subdued, and traditional European hop varieties impart subtle aromas. But the most important ingredient in lager brewing is the Saccharomyces pastorianus yeast, which produces the exceptionally clean flavor profile of lager fermentations.

Lager brewing: a unique process, from boil, to fermentation and maturation.

The lager brewing process is also unique in many ways. A stepped or decoction mash is used to improve conversion and wort quality when using lower quality malts or unmalted adjuncts. A long and vigorous boil is important to reduce levels of DMS in the beer. Fermentation of S. pastorianus lager yeast is performed at low temperatures to produce a clean and neutral flavor profile. A diacetyl rest is normally performed by increasing the temperature at the end of fermentation to encourage reabsorption of diacetyl by the yeast. An extended maturation (lagering) period is used to allow the yeast to further reduce off-flavors to achieve an exceptionally clean flavor profile. Enzymes and process aids are more commonly used when brewing lager beer compared to ale as they can increase efficiency, reduce waste, and improve the overall quality, stability, and profitability of the product.

Enhancing Lager Beer Flavor with Quality Control and Sensory Training

A high level of quality control is imperative when brewing lagers. Off-flavors have nowhere to hide, and even small variations in the raw materials or brewing process can impact the flavor profile. Robust cleaning and sanitation procedures are required to avoid contamination, which should be verified by testing samples in the lab. Yeast health and viability is especially important to producing a clean flavor profile. A sensory panel is a powerful tool for the early detection of off-flavors to facilitate corrective actions and ensure product consistency.

This technical paper is a general reference for the most important control points to help you to craft consistent and high-quality lager beers. Whether you are a large multinational brewery, a smaller craft brewery, or a homebrewer, lager brewing has never been more accessible.

To learn more, download our PDF here:

Published Mar 2, 2023 | Updated Nov 29, 2023

Related articles

Need specific information?

Talk to an expert